Considerations for Working alongside Plant & Road

Keep People and Vehicles Apart at the construction workplace and when vehicles enter or exit the workplace:

- Providing separate traffic routes for pedestrians and vehicles.

- Providing separate clearly marked pedestrian walkways that take a direct route.

- Creating vehicle exclusion zones for pedestrian-only areas, for example around tearooms, amenities and pedestrian entrances.

- Installing barriers, traffic control barricades, chains, tape or bollards to create exclusion zones for pedestrians.

- Ensuring a competent person with the necessary training or qualifications directs powered mobile plant when it operates near workers or other plant.

- Designating specific parking areas for workers’ and visitors’ vehicles outside the construction area.

- Providing clearly signed and lit crossing points where walkways cross roadways, so drivers and people can see each other clearly.

- Using traffic controllers, mirrors, stop signs or warning devices at site exits to make sure drivers can see or are aware of people before driving out onto public roads.

- Avoiding blocking walkways so people do not have to step onto the vehicle route.

- Scheduling work so vehicles, powered mobile plant and pedestrians are not in the same area at the same time.

Any remaining risk must be minimised using PPE, e.g. high visibility clothing.

A combination of the controls set out above may be used if a single control is not enough to minimise the risks.

Minimising vehicle movements

Planning can help minimise vehicle movement around a workplace.

To control vehicle interaction and limit the number of vehicles at a workplace consider:

- planning storage areas so delivery vehicles do not have to cross the site

- providing vehicle parking for workers and visitors away from the work area

- controlling entry to the work area e.g. by using boom gates, and

- scheduling work to minimise the number of vehicles operating in the same area at the same time.

Reversing vehicles

Where possible, avoid the need for vehicles to reverse as this is a major cause of fatal incidents.

One-way road systems and turning circles can minimise risks, especially in storage areas.

Where this is not possible other control measures should be considered, including:

- using mirrors, reversing warning alarms, sensors and cameras

- ensuring a signal person wearing high visibility clothing assists the driver who cannot see clearly behind their vehicle—the driver should always be able to see the signaller

- ensuring workers and other people are familiar with reversing areas and these areas are clearly marked, and

- ensuring plant operators are aware of workers who may be in the vicinity of the swing radius, articulation points and overhead load movement of their vehicle

Signs, warning devices and visibility

Signs should be used to alert workers and pedestrians to potential hazards from vehicles entering and exiting the construction workplace and other requirements like pedestrian exclusion zones.

Traffic routes should be clearly signed to indicate restricted parking, visitor parking, headroom, speed limits, vehicle movement, key site areas and other route hazards. Standard road signs should be used where possible and speed limits should be implemented and enforced.

If there is a possibility of powered mobile plant colliding with pedestrians or other powered mobile plant, the person with management or control of the plant must ensure the plant has a device to warn people at risk from the movement of the plant.

PCBUs must also ensure, so far as is reasonably practicable, lighting is provided to allow workers to carry out their work without risk to health and safety. Bad weather, shadows from plant and blind spots can reduce visibility.

The following control measures should be considered to manage risks:

- installing mirrors, reversing cameras, sensors and alarms to help drivers see or be aware of movement around the vehicle

- installing visual warning devices like flashing lights and high-visibility markings for powered mobile plant

- implementing safe systems of work to stop loads being carried forward where they impair clear vision

- appointing a trained person to control manoeuvres

- ensuring high-visibility or reflective clothing is worn by workers, plant operators and pedestrians at the workplace

- using communication methods like: radio—however ensure a back-up communication process is in place if it fails, and line of sight communication e.g. hand signals or cap lamp light signals. The person receiving the message should acknowledge the message has been received and understood.

Speed management

Temporary speed zones may be implemented where the consequence of speed through a work zone is not apparent to drivers and operators of plant and, therefore, they are unlikely to reduce speed to a safer level.

The speed limit selected for the work zone depends on several factors, such as the degree of vehicle and pedestrian conflict, the type and extent of the work, the characteristics of the road, and the separation between workers and the passing traffic lanes.

To be effective, work zone speed limits should:

- not be used alone or in place of more effective means of traffic control, rather they should be used in combination with such controls

- be used in conjunction with other signs or devices required by the site conditions, and

- only be used while work is being undertaken or temporary road conditions exist that are hazardous to safety.

Approval from the relevant road authority is required when changing speed limits on a public road.

Shoulders, Medians, Verges and Footpaths with Workers on Foot or Small Plant Items Only

These works may be carried out without any support vehicle on the roadway – Examples of this type of work include (but are not limited to):

· mowing, tilling, seeding, weed spraying

· garden maintenance

· minor tree clearing

· herbicide spraying

· road edge guide post repairs

Prior to undertaking these work activities, a risk assessment shall be undertaken to ensure the works can be safely completed.

When undertaking any works on medians, the median must be a minimum width of 1.2 m for this clause to apply.

If all workers are exclusively behind a safety barrier and are clear of the deflection zone for the safety barrier system, no additional methods of protection are required.

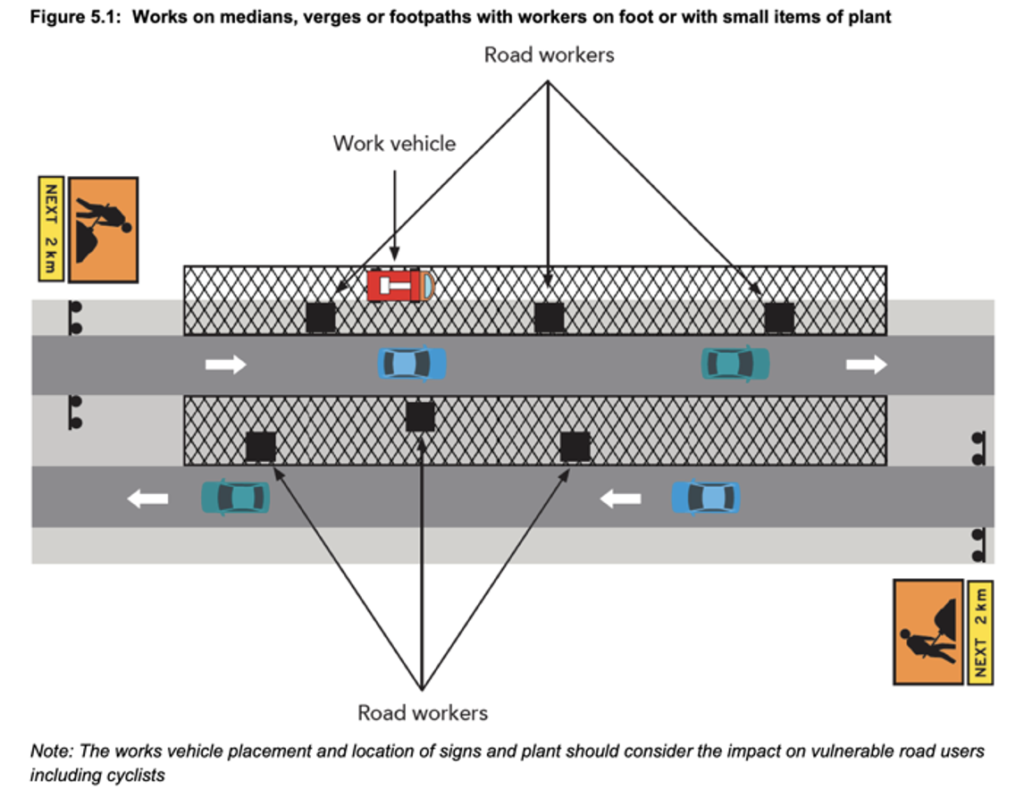

The typical works on shoulders, medians, verges and footpaths include:

· advance signs

· vehicle mounted warning device on the works vehicle – flashing light

Figure 5.1 illustrates an example of works outside of a traffic lane that involve workers on foot.

If you are working in the footpath location and speeds are under 80km per hr then no vehicle lights are required

But if working on median strip then lights on vehicle will be required and vehicle on road as per the drawing below

If above 80km per hour then a traffic management advisor must be consulted to advise about a TMP

Crew boss to always check with team leaders if unsure of traffic management requirements.

Work areas is outside traffic lanes

Clearance from the work area is one of the following:

a) if the speed is 60 km/h or less, the work area does not encroach into the live traffic lane

b) if the speed is more than 60 km/h but equal to or less than 80 km/h, the work area is at least 1.2 m clear to the edge of the traffic lane

c) if the speed is more than 80 km/h, the work area is at least 3 m clear to the edge of the traffic lane

When working on Median strips >= 1.2m wide and speed is less than 80km then also have a work ute with a flashing lights and signage

A vehicle mounted warning device is displayed on the work vehicles and not obscured

As works are frequently changing or progressively moving, at each advance warning sign location, the following signs shall be used:

· Workers (symbolic) sign

· NEXT 2km sign, NEXT 1 km, NEXT 500 m sign (sign as appropriate to length of work area).

Equipment or materials which are brought onto the work area should be unloaded from the non-traffic side of a stationary work vehicle, or the rear of a stationary work vehicle with a lookout person or shadow vehicle in place.

We need to assess the need for Traffic Control measures

We will consider:

· Access and egress requirements for the site;

· Delivery times of materials and equipment (e.g. peak hour traffic)

· Amount of traffic;

· Statutory signed speed limits.

· Reduction of speed limits.

· Duration of possible obstruction (if any);

· Any other applicable issues to consider; and

· We will assess the requirements for traffic barricades to protect the workers.

Plant/Machinery warning signals (flashing lights and/or beepers) are operative and working.

We will work during the hours prescribed by local laws and regulations and where practicable at off-peak times.

We will post warning signs in appropriate locations and if necessary isolate from the public (e.g. witches hats, barricades around vehicles, plant, machinery and site)

We will request the client to provide accredited traffic management personnel to manage traffic where required.

Spotters used for work areas where other workers and/or pedestrians are present.

Methods:

· Visual inspection each day before work commences

· Constant awareness

· Workers supervised at all times.

· Use of ‘Competent Persons’ where required.

· Use of Hi Visibility Clothing at all times

Workers required to work at night, or low light – having at least two workers working at any time, consider requesting client for additional lighting, wearing fluorescent and/or retroreflective clothing including vests and gaiters